A key component of their business is the design, manufacture and installation of commercial refrigeration systems and kitchens. They offer high grade materials and custom design to ensure equipment is designed to fit the space, meet food hygiene standards and performs in an Australian climate.

The Challenge of Offering Custom Signage

Typically ASM projects are completed within a three week period. This includes a custom design, manufacture and shipping, with the option for installation. This places extreme time pressures on the production timeline which has meant ASM have been unable to provide lasered signage due to lead times of 5-10 days being quoted by potential suppliers. The labelling of cabinet controls have to date been identified with stickers that adhere to the stainless steel. Clients were satisfied with this solution but on occasions when ASM revisited client sites where cabinets had been installed for an extended period of time, the labels were prone to fading or peeling meaning the switches or buttons had become unidentifiable. General Manager of Advance Steel Metal Shane Evans wanted to offer a more permanent solution that would last the duration of the equipment. “We are continuously looking for ways to add value to our clients and the benefits of custom lasered signage is multi-fold. Clearly identified controls are important when training new staff and also eliminates the risk of incorrect use by all staff. We had explored the use of etched plates which would then need to be attached onto the cabinet panels but this impacted the production time and lasering directly onto the stainless steel panel eliminates any risk of ingression of food which is critical in a food preparation area.”

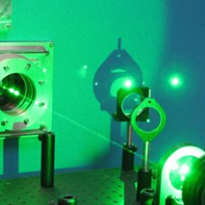

APC Technology’s Innovation Hub Enables Quick Turnaround of Custom Signage

APC Technology have invested in cutting edge technologies and staff training to ensure we can offer our clients cost efficiencies within the design and production cycle. Our Innovation Hub includes 3D printing and industrial lasering however it has also enabled us to offer complimentary services including custom signage. ASM approached APC Technology to discuss the possibility of producing custom signage within their lead time.

Neil Whitburn, Advanced Manufacturing Technician explained the process, “The first step is to create a CAD drawing of the panel and place the text based on the client’s specifications. As we have in-house CAD capabilities every aspect of the project can be completed in our head office. Once the initial drawing is complete and signed off it becomes an inexpensive option to update labelling for each client’s requirements. The laser material can either be supplied by the client or APC Technology. Our industrial laser is able to cut a range of materials include an array of metals, wood and man-made materials. In the case of ASM the panels were supplied and once set up was complete, the job was finished within an hour.”

Shane commented on the quick turnaround. “We found APC Technology could react to our short lead times and were also able to maintain the highest quality with their in-house laser capabilities. The first time we offered this service to a client we had 48 hours to ensure the signage was completed and back at our factory. The end result looked extremely professional and completed within a timeline which will enable us to offer this option to all our clients in the future.”

About ASM

Advance Sheet Metal has been established since 1997 as an aid to the South Coast Shopfitters for their Stainless Steel fit out requirements including Custom Refrigeration, Exhaust Canopies, Bain Marie, Warmer Cabinets and General Stainless Steel work including Balustrades and Hand Rails.

(1)-205x205.jpg)