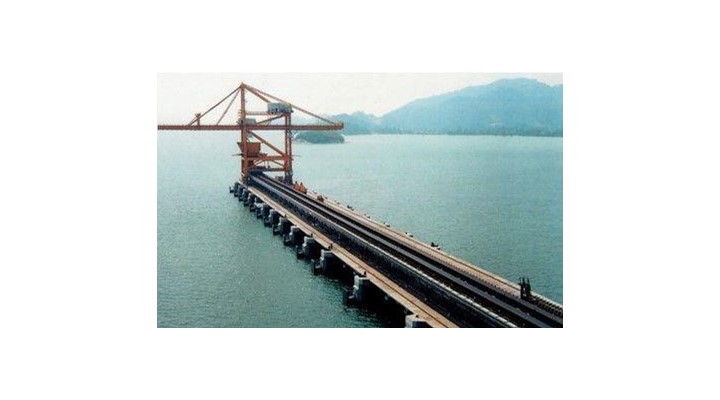

Whenever design engineers have to guide hoses and power and data cables in moving applications with long travels (more than 100 metres), the question arises of which energy supply system is the most efficient, especially considering such factors as reliability, maintainability, and future security? A motor cable drum? Or an energy chain? The advantages and disadvantages of the two systems are explored below.

Candidate 1: The motor cable drum

A proven energy supply that has been in use for decades – in applications such as cranes, transfer carriages, and the bulk material industry. The principle is simple. It is in its simplest form like a garden hose reel. When a gantry crane, for example, moves back and forth on its four supports, the cable is deposited on a prepared surface on the ground and is rolled back up on a drum mounted on one of the supports.

There are several variants for retracting the cable. In addition to motorised drums, there are designs for shorter travels that work with spring force: the rolling action is normally either cylindrical or spiral rolling. In the cylindrical form, also called broad rolling, the cable first rolls up from left to right along the drum body. Then it rolls up vertically, layer by layer. Spiral rolling works differently. The cable is stacked immediately after the first rotation.

The market for cable drums is growing. A key region is North America, and one reason is because the demand for cranes in the northern United States is rising. Another booming region is the Asia-Pacific, especially China and Japan. Among the reasons for this is urbanisation and a flourishing construction industry. According to Persistence Market Research, a market research institute, the global market volume will be more than $3.4 billion in 2026.

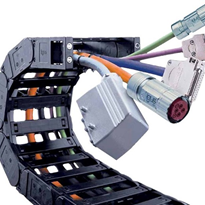

Candidate 2: The energy chain

An alternative for guiding cables on cranes, handling portals, or stackers/reclaimers is the so-called energy chain. This option is a mobile protective cage. It consists of parallel side links that are connected with crossbars along the top and bottom of the carrier. When the system moves, the chain folds, and the upper run glides on the lower run. No motor is required; the chain is attached to the crane's boom, for example, and moves with the movement of the crane.

Like the cable reel, the energy chain has been well-tried. Inventor Gilbert Waninger launched the chain in 1953. At the time, it was entirely made of steel, but today's manufacturers are more flexible. Since 1969, companies have developed high-performance plastics that can be used under a wide variety of environmental conditions – constant contact with salt water and heat in metal works, for example.

Energy chain vs. motor cable drum – Round 1: Installation space and weight

Energy chains generally have weight advantages for long travels. If the chain folds, the upper and lower run reach a height of around 800 mm, depending on filling and chain series. This makes them compact. Motorised cable drums operate differently. They do not require guide troughs, saving space on the user’s travel path. But in many applications, their drums have diameters of 6,000 mm or more. If this space is not available, the cable drum cannot be used as a solution. Another disadvantage of drums is that they are relatively heavy. This makes systems heavier and lowers their energy efficiency. The crane's structure must also be designed for this additional load. Sample calculation: for a travel of 400 metres in length and a cable weight of 10 kg/m, the additional weight of the rolled-up cable is about 4 t. Then there is the weight of the drum, the steel structure, and the drive technology. Energy chains made of high-performance polymers, on the other hand, are much lighter and contribute to energy savings. No additional load must be calculated on the crane.

Round 2: Assembly

Motor cable drums may have an advantage in this round, since their functionality is very simple. It is just as easy and fast to assemble the drums. Energy chains are also relatively quick to assemble, especially when users order the system with cables and plug-in connectors so that it is ready to connect. However, only qualified technicians should carry out the assembly. For long travels, a guide trough is obligatory for gliding applications (when the upper run lies on the lower run), and an energy chain riser guard or an enclosure that protects the system from weather may be recommended as necessary. This allows safe operation under any weather conditions.

Round 3: Cable protection

The task of motor cable drums and energy chains is to protect moving cables and hoses from mechanical loads. The chain comes out ahead here, since it guides cables and hoses safely through the interior separation and relieves strain at the fixed and moving ends. They are subjected to neither tensile forces nor high mechanical loads during movement. Moreover, some high-performance polymers have vibration-damping properties. The cables and hoses are protected from wear along their entire length. Motorised cable drums operate differently. There is a constant tensile force during rolling and unrolling so that the cable experiences a greater load, reducing its service life.

Round 4: Wear and maintenance

Motor cable drum manufacturers now have corrosion largely under control. But in extreme environments, such as offshore facilities, rust can force operators to intensively maintain or replace their motorised drums over the course of the years. Bearings and the slip ring body are the elements that are especially affected by corrosion and wear. At worst, this can cause long, expensive system downtime. Then there is occasional maintenance work for guide elements, clamp connections, and motor and switch deflectors. This means that operating motor cable drums involves time and expenditure. Energy chains operate differently. High-performance polymer variants are resistant to chemicals, saltwater, and UV radiation. The result is that, in some applications, energy chains can be operated for almost ten years with hardly any maintenance.

Round 5: Combinability and extendability

Transmitting energy and data via motor cable drums requires either different drums or expensive special cables. If additional fibre optic cables or hoses for supplying air, water, or oil must be moved, additional drums and components are indispensable. Energy chains, on the other hand, accommodate the use of a wide variety of cables and hoses in a single system from the very beginning. In order to react flexibly to technological trends, they allow easy addition of other cables if reserve space is set aside from the beginning of operation. This is not true of motor cable drums: it is very difficult to add hoses or cables later on. To do so, the operator needs either a special design or additional drums.

Round 6: Compatibility with Industry 4.0

In the Industry 4.0 era, more and more users are integrating machines and systems into the Internet of Things in order to digitise processes. This enables systems to autonomously call attention to a problem. Energy chains come out ahead here. Manufacturers have begun equipping energy chains with break detection systems and push/pull force systems. Anomalies in set parameters, such as those caused by breakage in a chain link or blockage in the energy chain run, can activate emergency stop systems or trigger maintenance missions in good time. Before there is expensive system failure.

Round 7: Operation and speed

Today, industry everywhere requires faster turnaround times, which necessitates faster and faster travel speeds for moving equipment. A system with motor cable drums can achieve average travel speeds of up to 120 m/min (up to 300 m/min with limitations). An energy chain system with integrated rollers in the chain link can reach travel speeds of 600 m/min. And that speed is constant across the entire distance. Systems with motor cable drums must brake when they reach or pass infeed points so that the cable can be properly rolled up or deflected.

Conclusion

Energy chain or motor cable drum: which energy supply system comes out ahead? There is no blanket answer because, in the industrial world, no two applications have exactly the same conditions. Different elements are weighted differently. Some points favour the motor cable drum – among these are its simple assembly. Others, such as cable protection, largely maintenance-free operation, and the extendibility, favour the energy chain. Treotham offers a large range of lubrication free igus energy chains for a variety of applications and industries.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)