Predator™ v-belts can handle up to 2.2 times more power the equivalent size standard v-belt. A more compact drive that weighs less, puts less strain on costlier components, and uses fewer belts. All of which saves you money. See the difference in the following examples:

Compared with standard v-belt drives, the compact Predator™ drive provides greater power capacity in half the width and weight, at a third of the cost, with no change in shaft loads. Predator™ V-belts provide the ideal solution to replace costly, made to order, 8V belt drive pulleys with standard SPB or SPC.

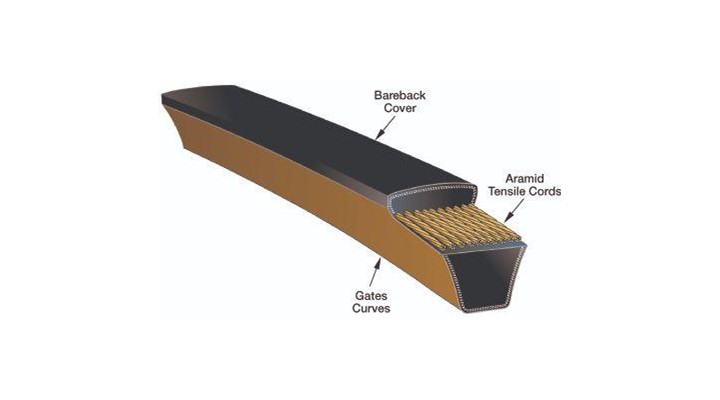

All Gates® Predator™ v-belts feature:

Bareback Cover

Reduce friction and heat buildup under shock loads and slippage with abrasive and puncture- resistant bareback (non-rubber) double layer fabric cover.

Aramid Tensile Cords

Minimal need for re-tensioning due to stronger-than-steel aramid fibre or Kevlar® tensile cords that reduce belt stretch by 50% over standard v-belts.

Premium Compound

Oil and heat resistant chloroprene compound body, rated for 82°C, outperforms other rubbers in harsh operating conditions.

Gates® Curves

Extend drive life with the patented curved sidewall that allows belt to enter the sheave groove cleanly and smoothly, reducing the sidewall wear on belt and sheave.

For more information on Gates® Predator™ range go to www.gatesaustralia.com.au/Predator.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-375x300-205x205.jpg)