Traditionally, cribbing and blocking of equipment and machines in both workshops and on-site maintenance has been done using timber blocks.

However, users need be wary of the inherent dangers of this, as timber blocks can suffer permanent damage without showing any visible signs.

Consider for example: an application where a piece of wood being used to support a machine is overloaded, its internal fibres damaged. Because the strength of a block relies on the wood fibres being completely connected one to another, in this damaged example load-bearing effectiveness is now compromised. Further, use of such a timber block that shows no visible sign of damage, yet is internally unsound, yields a potentially unsafe work environment.

Another limitation of timber blocks is that no two pieces will have the same load-bearing capacity. Furthermore, as a timber block ages, uncertainty regarding its load-bearing capacity increases. These structural uncertainties, combined with: questionable absorbency, risk of splinters, cracking and possible failure under load, it is clear that the time has come for modern, safer alternatives to timber be investigated.

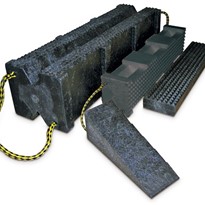

Dura Crib cribbing and blocking products are engineered as a fit-for-purpose tool for supporting machinery and equipment when carrying out assembly, repairs and maintenance tasks. This lightweight, splinter-free, non-absorbent and environmentally sustainable product range is manufactured from 100% recycled, high-density polyethylene (HDPE) to a strict formula and following quality control processes.

Working load limits of the Dura Crib blocks ranged between 30.6 to 60.8 kg/cm2 (3.0 to 6.0 Mpa) at 25ºC, tested in accordance with AS1170 and AS 2498. Maximum load bearing capacities of individual blocks range from 9,300kg to 110,000kg. Aggressive pyramid surfaces ensure positive locking of the blocks in stacks and reduce the likelihood of slippage.

Unlike traditional timber, Dura Crib blocks are available in both ultra-strength black and high-vis yellow and are resistant to fuels, oils, organic substances and most commonly used industrial chemicals. All Dura Crib products are backed by a 50 year warranty against splitting, rot, fluid absorption, termites and mould.

The innovative Dura Crib cribbing blocks have already been proven under some of the toughest safety regimes. Existing applications may be found in industries such as mining, resources, construction and building, and they have been successfully used in rescue and recovery, materials handling, industrial maintenance and safety and rail transport.

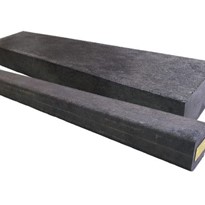

Above illustration showing artist's impression of potential internal fibre damage of a timber block. Unless there are external signs of block failure (cracks, splits, indentations) any internal damage will not be identified during a visual inspection.

-205x205.jpg)