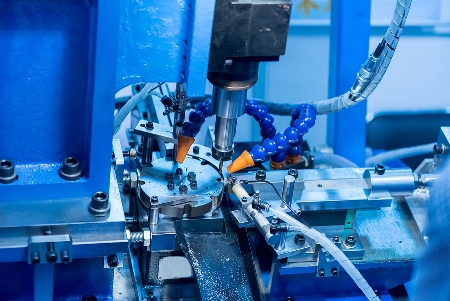

With a CNC milling device you can cut and drill along multiple axes creating a diverse range of slots, holes and shapes. So how do you choose the right one for your requirements? Here are a few tips to find the right CNC milling machine for your needs.

Assess your angles and axes

CNC milling devices are grouped by axes. X and Y devices are the simplest working horizontally forward and back and side to side. Is that all you need or is your work more complex than that?

If it is you can add vertical Z movements and diagonal W movements across a vertical plane. Most CNC milling devices give you at least X, Y and Z with 3 to 5 axes. But if your job requires some seriously complex cutting along 5 axes, you'll need to factor computer-aided manufacturing (CAM) software into the equation to plan and control the process.

Assess your numbers

Are you planning a large production run with a fairly straightforward design? While CNC milling devices are capable of working in bulk, they're still better suited to smaller production runs of high detail. They're also ideal for creating prototypes. So weigh up complexity and quantity before you take the CNC milling option.

Get good cutters

Your CNC milling job can be as meticulously planned and programmed as you like, but it's only as good as its cutters. Run-of-the-mill cutters will give run-of-the-mill results, so avoid cheap unbranded cutters. Go for branded options from reputable suppliers. Carbide is your best bet for diversity of uses, but high speed steel (HSS) is cheaper and more forgiving.

Vice and clamp for good measure

Again, detailed, multiple axis parts won't make the cut if they shift even a fraction during the cutting process. So invest in a top quality vice and clamping kit. Remember, even the most miniscule shift will throw your cutting right out of kilter, so get a good vice, mount it to the t-slots in your table and clamp it.