Weighing the pros and cons of the different welding processes and the projects you are most likely going to use your welder for, is essential to making your selection.

As the Development Engineer for Equipment with Welding Industries of Australia (WIA) Willem Corbett says, “There is no single welding process suitable for all welding situations. What’s important is understanding which process is best suited to your application.”

The most common welding processes include:

- Gas Metal Arc Welding (GMAW) often referred to as Metal Inert Gas (MIG),

- Gas Tungsten Arc Welding (GTAW) often referred to as Tungsten Inert Gas (TIG),

- Flux-Cored Arc Welding ((FCAW),

- Manual Metal Arc Welding (MMAW) often referred to as ‘Stick’ welding;

Each of which has its own set of benefits and limitations. According to Willem, there are a number of factors that must be considered to determine which welding machine will be the most appropriate for your needs. These include:

- Type of material being welded

- Thickness of material

- Required weld metallurgy

- Welding position

- Available power supply, for example, single phase or three phase

- Amount of available current

- Time requirements

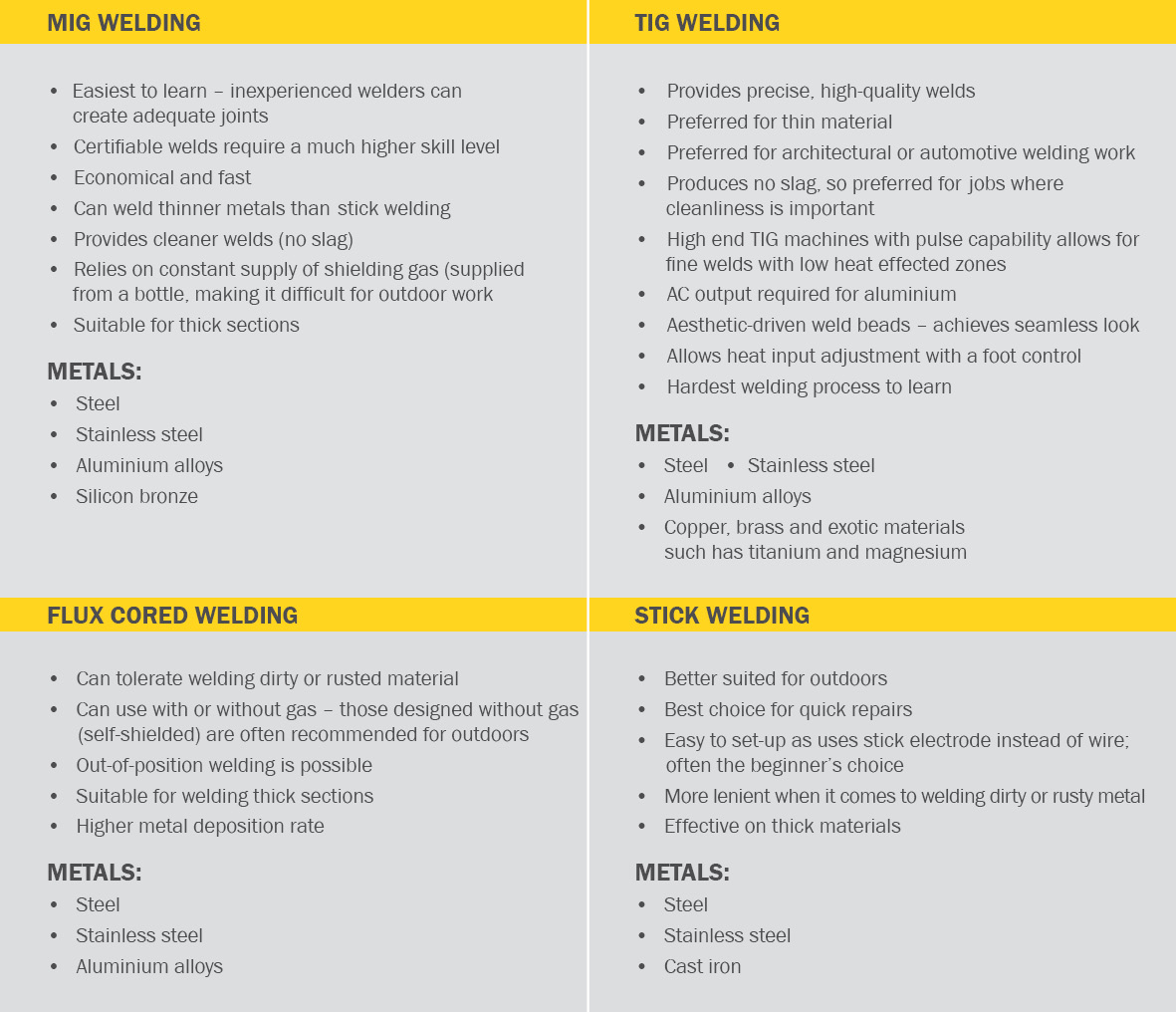

The below table provides a comparison of the different welding processes and what metals they can work with:

Besides the type of process and the metals you wish to weld, Willem from WIA says it’s also important to consider the required welding current and the amount of weld time. This is important when determining the duty cycle of the machine.

Something else that needs to be considered is the varying amperage and power requirements of the machine. For example, will the user always weld with high current or only occasionally? Additionally, there are other expenses to consider such as the cost of gas verses using gasless for MIG, or using stick. “If you are looking to purchase a machine, take the time to define what you will use it for and come to us (WIA) for advice,” says Willem. “We can go through the different options with you and help you make the right choice. Because matching you with the right machine for your application could be the difference between a profit and a loss.”

The WIA range includes a large variety of machines from single and three phase MIG welders, Arc and TIG machines and multi-process welding solutions.