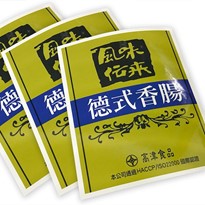

Labels should identify, distinguish and promote your brand, bringing it to life! Even the simplest product would be quite lost without its label.

This introductory guide explains the different components that make up a custom, adhesive label, the variety of printing and finishing options available and explores some operational and lifespan factors that should be considered to ensure the best result.

Label Construction

Facestock- The Presenter

Facestock is the medium that physically carries your label’s printed information and decorative aspects. Its biggest task is taking care of presentation.

Adhesive- The Performer

As the name suggests, adhesive is the tacky coating that attaches your face stock to the product or packaging surface. Its performance is critical in ensuring the label is easy to apply and remains affixed for the life of the product.

Release Coating & Liner- The Carrier

Liner is the backing paper that carries your label and preserves its adhesive prior to use. Ideally it has a high-grade silicon coating which offers optimal release qualities in high speed dispensing environments.

Label Components Considerations

The material combinations of face stocks and adhesives is almost endless. Understanding the conditions and processes the label faces during its life helps highlight the factors that should be considered when choosing label materials and so ensure the best outcome for the label and product.

Product & Environment

The product’s surface and shape will impact the label material choice, as will the temperature at both the time of application, and the service life of the product.

Adhesive

Acrylic or Hot Melt adhesives are commonly used. Factors affecting adhesive choice are temperature, the nature of the product’s surface and other conditions likely to occur within the supply chain environment. Adhesives react differently depending on the surface energy of the product, for example carton vs glass vs different types of plastic. Label adhesive can be permanent, removable or even initially repositionable and then permanent.

Protection

Some labels require additional protection against the environment and consideration should be given to whether moisture or consideration occurs at either the point of application or during the service life of the product, and also whether the label will be applied before or after the product is filled. If the product is to be stored outdoors, the image will need to be light-fast. Finally, does the label image need protection against scuffing or marking caused by contact or rubbing during transportation?

Application

How the label is applied to the product is also worth taking into account in the planning stages of a label – will it be applied by hand or by high speed applicator. Sometimes variable information, for example, product description, use-by date, barcode, asset or ingredients information will be over-printed at a later date by a laser printer or thermal printer or automated print and apply system, and this should be taken into account in the label’s design. Is the product’s packaging recyclable, and so does the label need to meet recycling requirements. Are there any other factors unique to your product or process?

A comprehensive understanding how and where the label is used is vital in determining the best material choices for the label’s components. If ‘under-spec’ed the label will not perform as required to promote your brand. Conversely if ‘over-spec’ed, you will end up paying for unnecessary, expensive materials.

Label Manufacturing Process

Fast, Efficient, Flexo

Flexographic printing is globally recognised as the label industry’s leading printing technology. Combining fast press speeds, excellent print quality and efficient plate and colour change regimen, Flexo ensures a flexible, efficient and cost-effective printing process. Ultimately, each order requires less press time, which reduces costs and lead times for customers while providing outstanding image and colour integrity

Living Colour and the CMYK Process

CMYK or Four Colour Process technology is the industry standard means of transferring full colour artwork onto a substrate through a printing press. Using combinations of four colours - Cyan (C), Magenta (M), Yellow (Y) and Black (K) and incorporating half tone dots & solids - printers can achieve photographic quality reproduction and solid colours with maximum efficiency.

So how do these four colours work together to generate a full colour picture?

The process starts with your digital artwork file. Graphic design software reworks your picture into four colours: cyan, magenta, yellow and black. These are known as separations. From here four printing plates are output with half tone dots and solid areas - which when later combined on press re-create the full colour image onto the substrate.

Spot Colour Printing - Perfectionist Colour Quality

While CMYK printing is suitable for reproducing literally millions of images, it cannot match our own eyes. There are colours that cannot be achieved - fluoro, metallic and particularly intense colours are examples. These colours are described as “out of gamut”.

Spot colour is used to print type, images or blocks from your artwork, eg; a logo, in a specialty colour. It is not suitable for reproducing photographic style images.

Your particular spot colour is made by mixing specialty ink pigments to achieve an exact colour match. The Pantone Matching System (PMS) is the universal reference point for the recipes to make spot colours - you may already be familiar with the Pantone colour selection books.

Spot colour can be used in addition to CMYK printing, or on its own. Printing plates are prepared in a similar fashion, and mounted, then loaded into the press in the same way. Each colour is loaded into a separate print deck.

Plates are mounted, then loaded into the flexographic press, and each of the four colours is positioned into separate print decks in sequence. The substrate travels through the press just once and a full colour image is produced.

Surface Coatings

Surface coatings and laminates can be applied to your prime label in situations where special presentation or protection is required. From a presentation perspective, a surface coating can enhance colours, add a glossier or more matt appearance and enhance the prestige of your label... and ultimately your product. In other cases where moisture, chemicals or scuffing can threaten the life or performance of the label, a coating will protect the substrate and printed images. Common finishes used include:

- Laminate - Creates an excellent barrier to protect against scuffing or corrosion - available in both Matt & Gloss.

- UV Varnish - Creates a gloss effect and protects to a lesser degree.

- Water Based Varnish - Used in specialty overprint applications.

Obviously, surface coatings add an extra production cost and are not suitable for every application, Your label supplier can assist in evaluating the cost/effect benefits of a surface coating.

Die Cutting

A die or dies are used to cut the shape of the label. Rectangles, squares, circles, special shapes, perforations, undercuts (die cuts in label liner) are all options available to suit the application. This is a vital part of the process as exact pressure is required for clean cutting, while not cutting too deep, causing die strike, and compromising the integrity of the liner. Die cutting is performed after the printing process, and the matrix waste material is removed, all still in the one press pass.

Design & Planning

If you have a number of similar labels in your range, clever design and strategic print planning can allow different labels to be printed at the same time, or even just share common print plates, creating efficiency of scale, reducing costs in printing plates, and job times.

Finished Format

Depending on the application method, labels can be supplied on rolls, fan-folded or supplied in sheet format.

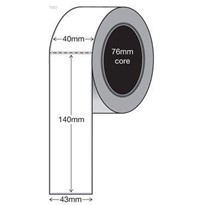

“Rolls” of labels supplied wound around cores. Both the inner diameter of the core and the outer diameter of the finished roll of labels may need to be defined based on the type of application equipment, as well as whether the labels will be wound onto the roll facing out (normal-wound) or facing in (reverse-wound).

“Fanfold” refers to those labels supplied in stacks with alternating folds, as opposed to being supplied on cores. Fanfold labels can be used where application equipment may not accommodate the roll size needed and/or where larger quantities are preferred to minimize the frequency and number of roll changes.

“Sheet format” labels are cut so that each label or “label-set” is on an individual sheet and are often used when the labels are over-printed by a laser printer.

To download insignia's guide to customer product labels please click here.

For more information, contact us.