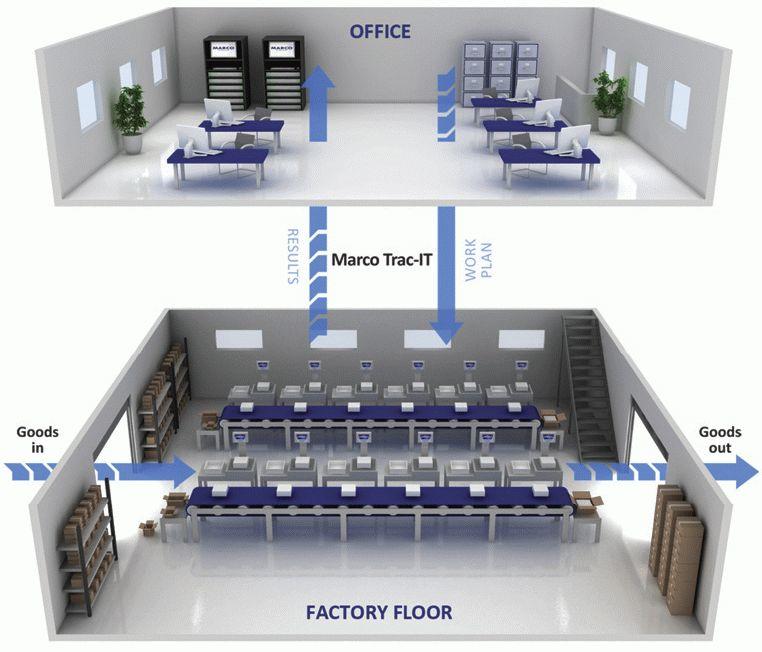

Manufacturing Execution Systems (MES) uses computerised systems to bring important real-time control to manufacturing processes within the food sector, to document and track the transformation of raw material into finished goods. This helps decision-makers understand how current conditions on the plant floor can be optimised to improve production output, which improves productivity and profitability.

Select Equip’s director James White said that, “Manufacturing Execution Systems have a reputation for being complex and time-consuming to install, requiring a lot of input from all sides. However, with MARCO’s ‘off-the-shelf’ solution they have done all the work, so you won’t need to.”

Supplied by Select Equip, MARCO Trac-IT MES can be rapidly implemented and integrated within existing plant and ordering systems (ERP system), as all hardware and software is developed and therefore can be adjusted, which is suitable for companies of all sizes ranging from multinationals to small domestic packing operations.

It’s a combination of a variety of MARCO’s individual Trac-IT modules, brought together to maximise productivity, product consistency, and quality within facilities and provides a codified control of all procedures from goods-in to goods-out meaning there is total visibility across the entire operation. It also provides live, immediate data reported across all areas of production, providing instant and clear traceability across the packing line.

With this complete transparency across facilities in terms of data and product quality, it oversees accurate stock control at goods-in through to 100% labelling accuracy at goods-out. Plus, MARCO’s Yield Control Module and Waste Management Module also form a part of MES, allowing for consistent pack weight, real-time overpack reduction, and live waste data.

These aspects of MES alone, will dramatically reduce costly waste and increase productivity, in most cases by 30 per cent.

Few companies feel they can dedicate enough man-hours and resources to achieve a ‘fit-for-purpose MES, often dealing with 3rd parties for the more technical aspects of production. But with over 150,000 hours of software development, has seen the development of Marco’s market-leading, ‘off-the-shelf’ MARCO Trac-IT Manufacturing Execution System (MES) and is available through Select Equip, one of the leading food packaging equipment partners in Australia.

To find out Marco MES, please contact Select Equip.

-205x205.jpg)