Should you consider direct-digital manufacturing (DDM)? The answer is definitely "yes". In the long run, every engineering shop that currently has a CNC machine will one day also have an additive manufacturing (AM) machine of some kind in the future.

Leading 3D printing technology provider Stratasys this year celebrates the 10th anniversary of its Dimension line of 3D printers (distributed by Tasman Machinery in Australia), which has brought 3D printing technology to a broad audience and accelerated the trend of 3D printer use in the market, which has positive effects on local manufacturing in most developed economies, including Australia.

One of the most intriguing consequences of the increasing use of AM techniques is the potential to reverse the trend to outsource manufacturing to low-cost countries in order to avoid high labour and tooling costs.

This trend could potentially be reversed if companies instead purchased a DDM machine or 3D printer, which would give them a fixed cost base, reduce labour intensity and remove high tooling costs and time, potentially negating the incentive to outsource. It would be great to see more manufacturing processes return to Australia.

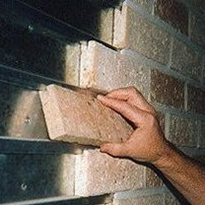

But the technology is not suited for every application. However, it is worth considering AM, or fused deposition modelling (FDM), developed by Stratasys (see picture), if your applications have one or more of these four attributes:

Low production volume

DDM is most appropriate for parts produced in quantities of less than 3000 per year. This is one reason that DDM is increasingly used in applications for jigs, fixtures and other tools used in the assembly process.

High design complexity

Although DDM can be used to produce simple objects, the cost and time advantages are more pronounced when parts have complex shapes, intricate designs or numerous features.

Additive processes such as FDM are insensitive to design complexity. Building material up layer-by-layer to complete the part eliminates problems such as creating internal cavities and complicated 3D contours. It also doesn't require the workpiece to be set up or re-fixtured multiple times.

High probability of change

Design changes can be expensive and time-consuming when using traditional subtractive manufacturing processes. On the other hand, DDM allows freedom to redesign at will.

Manufacturing a revised design is simply a matter of modifying the CAD data, exporting a new programming file and starting the machine.

There is no additional cost for rework or retooling, and there is no interruption in production schedules. In this way, DDM serves as a bridge to production — it provides flexibility to change a product's design after its launch.

High start-up investment

All subtractive manufacturing processes involve substantial investment of labour, time and money for toolpath creation, fixtures, moulds and machinery.

FDM has no tooling costs, and the waiting period for the first production parts may amount to only a few hours or a few days at most.

Advantages of using DDM for manufacturing

DDM is the process of using an additive fabrication system to create parts for end use. In fact, there is a growth in the number of manufacturers that are using additive fabrication systems to build a range of parts, such as components for new products, jigs, fixtures, hand tools and gages.

Design and engineering firms are finding further uses for fused deposition modelling (FDM) machines aside from the traditional rapid prototyping (RP) functionality.

Advantages at a glance:

- Complex parts can be produced without the need for highly skilled labour

- Parts can be produced as needed, eliminating the need for stock

- Part design can be based on function rather than manufacturing constraints

- Design changes can be implemented immediately at minimal cost

- Custom products can be produced to match customer requirements

*Dermid McKinley is the managing director of Tasman Machinery

-160x160-state_article-rel-cat.png)