HUMIDITY CONTROL IN TABLET AND CAPSULE MANUFACTURING

The preparation and storage of pharmaceutical products requires a controlled environment. Tablets, capsules and hygroscopic compounds are all vulnerable to temperature including being very sensitive to humidity.

Dehumidifiers for the Pharmaceutical Industry

Dehumidification is much more sophisticated than heating the space. Dehumidifiers work by recirculating the same air and physically removing the moisture from it. This eliminates the need to continuously reheat the incoming air.

Also, a commercial dehumidifier converts energy taken out of the room as moisture to create a ‘sensible energy’ that can be used to heat the room, which accelerates the drying process

COMMON HUMIDITY RELATED INDUSTRY PROBLEMS

The slightest fluctuation in humidity levels may compromise a whole batch of pharmaceuticals.

- Difficulties Maintaining Consistent Humidity Levels

Manufacturing laboratories have stringent testing standards and compliance measures usually requiring humidity levels of 20% Relative Humidity (RH). - Damage to Equipment Caused by Humidity

Excess moisture can cause structural damage to expensive equipment, damage crucial electronics and cause equipment to become faulty. - Increased Operating Costs and Energy Consumption

Laboratory environmental conditions need to be maintained 24/7. Running standard dehumidification of cool and reheat is usually costly and doesn’t maintain the ideal climate consistently.

ALL THESE ISSUES LEAD TO PRODUCTION DOWNTIME, DELAYS TO MARKET AND INCREASED OPERATING COSTS

CLIMATE CONTROL IN PHARMACEUTICAL MANUFACTURING

Storage Conditions for Gelatin Capsules

There are two different types of gelatin capsules, dry and hard. Once formed gelatin has to be dried carefully without excessive heat.

The manufacture of gelatin capsules requires precise temperatures and relative humidity (RH). For example, if the air temperature and

humidity used to dry gelatin is too low, it will set rapidly and becomes brittle. If air temperature and humidity is too high, the gelatin will not solidify correctly.

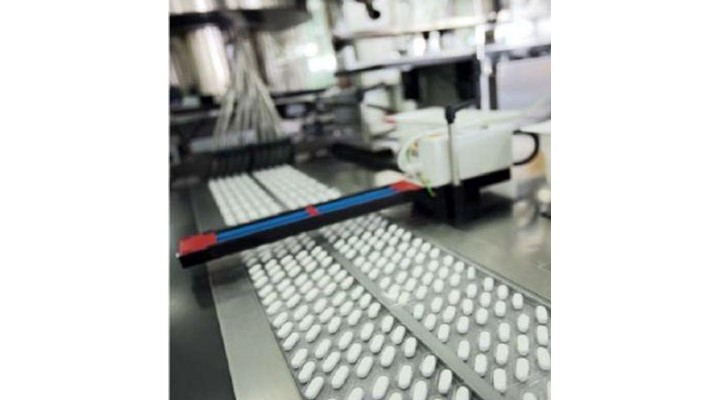

Humidity Control in Tablet Pan Coating

Coating for pharmaceutical products is done for a variety of reasons. The coating is applied using a drying process using a rotation pan.

Humiscope can supply dry air at a specific humidity and temperature level to evaporate moisture in the pan and allow the coating to dry on the base.

Effervescent Tablets and Relative Humidity

Effervescent tablets are dissolved in water before being consumed. Thus the ingredients of effervescent tablets are extremely hygroscopic.

To avoid unwanted moisture absorption, the relative humidity of the air must be kept at a low level during the manufacturing process until the product is enclosed in a moisture tight package.

Depending on your specific needs will determine the choice between a Desiccant Dehumidifier and a Mechanical (refrigerant) Dehumidifier.

Please contact us and we can discuss possible solutions for your business. We also offer a wide range of Dehumidifier rentals. Temporary dehumidifier hire during the more humid months has proven very successful for a variety of industries.

-720x400.jpg)