Understanding VFD Inverters

In the ever-evolving landscape of industrial technology, Variable Frequency Drive (VFD) inverters have emerged as transformative powerhouses. Often known as VFDs or AC drives, these electronic marvels have redefined how electric motors are controlled, offering a level of precision and adaptability that traditional fixed-speed motors simply cannot match. In this comprehensive exploration, we will dive deep into the intricate workings of VFD inverters, their diverse applications, and the profound impact they have had on industries across the globe.

The Art of Motor Control:

- At the heart of the VFD inverter's brilliance lies its ability to manage the essential elements of electric motor performance: speed, torque, and direction. This level of control is achieved through the manipulation of two fundamental parameters of electric power: frequency and voltage. The process by which VFD inverters bring this control to life is nothing short of remarkable.

Frequency and Voltage Manipulation:

- To comprehend the magic of VFD inverters, we must start with the initial step: rectification and conversion. When AC power is supplied to these devices, it is subjected to rectification, transforming it into direct current (DC) power through a rectifier circuit. This DC power lays the foundation for the transformative journey that follows. The pivotal moment arises when this DC power is inverted back into alternating current (AC) power. However, what sets VFD inverters apart is their capacity to sculpt this AC power output according to precise requirements. They can seamlessly vary both the output frequency and voltage to precisely match the dynamic demands of the connected electric motor.

Dynamic Control at Its Finest:

- Operating as the brains behind this intricate choreography, microcontrollers or digital signal processors (DSPs) within VFD inverters continuously monitor the motor's performance. These controllers take into account a multitude of factors, including motor speed and load conditions, ensuring that the motor operates in perfect harmony with the desired parameters. It's this dynamic control that makes VFD inverters stand out, enabling them to adapt and respond to real-time changes in motor operation.

Smooth Start and Stop:

- Another remarkable attribute of VFD inverters is their soft start and stop capabilities. These functions facilitate gradual acceleration and deceleration of the connected electric motor, eliminating sudden jolts and mechanical stresses during startup and shutdown. The result is not only an extended motor lifespan but also heightened safety and reliability within the system.

Applications Across Industries:

- The far-reaching applications of VFD inverters span across a plethora of industries. From precision manufacturing processes and state-of-the-art robotics to efficient heating, ventilation, and air conditioning (HVAC) systems in commercial and residential structures, VFD inverters have become indispensable. Their prowess shines in scenarios where precise motor control is paramount, filling the void left by conventional fixed-speed motors and ushering in new levels of flexibility, efficiency, and sustainability.

How VFD Inverters Work

- The fundamental principle behind VFD inverters lies in their ability to convert fixed-frequency AC power into variable-frequency AC power. Here's a simplified breakdown of how they operate:

- Rectification: Incoming AC power is first converted into DC power using a rectifier circuit.

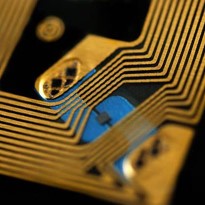

- Inversion: The DC power is then inverted back into AC power at the desired frequency and voltage using insulated gate bipolar transistors (IGBTs) or other semiconductor devices.

- Control: A microcontroller or digital signal processor (DSP) continuously monitors the motor's speed and load conditions. Based on this feedback, it adjusts the output frequency and voltage to maintain the desired performance.

- Acceleration and Deceleration: VFD inverters offer soft start and stop functions, gradually ramping up or down the motor's speed to avoid sudden mechanical stress.

Applications of VFD Inverters

- The versatility of VFD inverters is reflected in their wide range of applications across industries:

- Manufacturing: VFD inverters are integral in conveyor systems, CNC machinery, and production lines, where precise speed control ensures product quality and production efficiency.

- HVAC Systems: In commercial and residential buildings, VFD inverters optimize the operation of fans and pumps, resulting in substantial energy savings and improved comfort.

- Renewable Energy: VFD inverters play a crucial role in solar and wind power systems, converting variable DC power from solar panels and wind turbines into usable AC power.

- Transportation: Electric vehicles rely on VFD inverters for motor control, offering superior acceleration and regenerative braking.

- Mining and Water Treatment: VFD inverters enhance the efficiency of pumps and compressors in challenging environments.

- Oil and Gas: They are used in drilling rigs, ensuring precise control of drilling operations.

Key Benefits of VFD Inverters

- The adoption of VFD inverters brings several transformative advantages:

- Energy Efficiency: VFDs reduce energy consumption by matching motor speed to actual load requirements, resulting in substantial cost savings and reduced carbon emissions.

- Precision Control: Precise motor speed control improves process accuracy, quality, and reliability.

- Equipment Protection: VFDs extend the lifespan of motors and connected equipment by minimizing mechanical stress during startup and operation.

- Versatility: VFDs can be customized for various motor types, sizes, and applications.

- Soft Start and Stop: They offer smooth acceleration and deceleration, reducing wear on mechanical components and eliminating voltage sags.

Conclusion

Variable Frequency Drive inverters have revolutionized the way industries operate, offering unprecedented control, efficiency, and sustainability. With their adaptability to diverse applications and potential for substantial cost savings, VFD inverters continue to be a driving force in the quest for improved industrial processes and environmental responsibility. As industries evolve, VFD inverters will remain a cornerstone technology, delivering precision and efficiency to power the future.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-205x205.jpg)

-205x205.jpg)

-205x205.jpg)

-205x205.jpg)