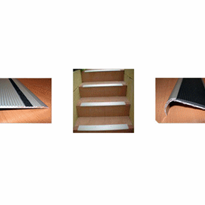

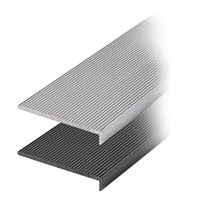

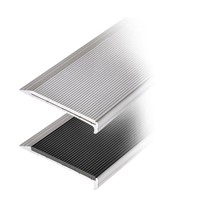

Are the longest wearing anti-slip stair nosings the longest lasting anti slip treads? Note that anti slip stair treads & bull nosings get very dirty and clogged up and renders any anti-slip grit used in the manufacturing of no consequence, pretty much made useless by the clogged-up dirt.

Hence, however hard or long wearing, whether it be anti-slip silica carbide, aluminium oxide, carborundum or other media, in the right environment the conventional stair nosings get dirty and become clogged with mud and slurry. So, how long is the actual anti-slip stair tread properties going to help? Definitely not for long, however much you may have paid for them.

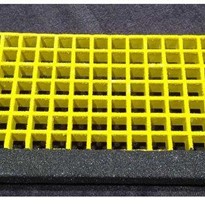

In this particular dirty and muddy environment where sludge is present, there are very limited options. Keeping your work boots in good working order with plenty of grip is sure to help in this situation. Using U-Tred anti-slip stair nosing in this type of environment is ideal. As you can see from the picture, below right, the U-Tred stair nosing sits just proud of the edge of the steps and still is able to provide anti-slip properties, even if the grating gets clogged.

Yes, maybe the muddy sludge will discolour them but the anti-slip cleats still work 100% when more conventional stair nosings are pretty much rendered useless. Thus, you get absolutely no return on investment and no boxes ticked on the safety audit in slippery areas on site with clogged grating.

Dirty clogged anti slip stair treads increase the percentage of a potential slip and fall—causing grief to both the employee and the employer. In both cases, someone will have to wear the cost of a potential first aid callout of loss of job for a responsible safety person on site.

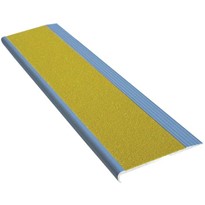

Now, for environments where aggressive chemicals, salty marine environments, and so on are present, one should consider using a different kind of non slip stair tread other than metal grates and the like that we are more familiar with.

An FRP (fibre-reinforced plastic) anti slip stair tread with anti-slip properties is the go. Consider the AMCO FRP grating and non slip stair tread. These non slip stair treads contain self-extinguishing, fire-retardant resins. And, the anti-slip surface integrated with quartz silica granules will provide your years of anti-slip service.

Our FRP Grating has excellent resistance to a wide range of corrosive chemicals. They are an ideal product for use in environments where rust, saline and acids are prevalent. Unlike metal grating, our FRP grating will not rust or corrode. Consider that many non slip stair treads are bolted on to the stairs. When corroded, these are then removed after reaching the end of their service life.

With our FRP grating and non slip stair treads, you save on huge labour cost involved when replacing older more conventional anti slip stair treads. Plus, you get peace-of-mind, as you don’t have to worry about future corrosion and having to work in future maintenance or replacement.

Contact us now for more information.

-205x205.jpg)