Typically, cleaned filters tend to last approximately half as long as new filters before they plug again. As a consequence, cleaned filters need to be replaced more frequently, and that means more changeouts, more downtime and more cleaning charges.

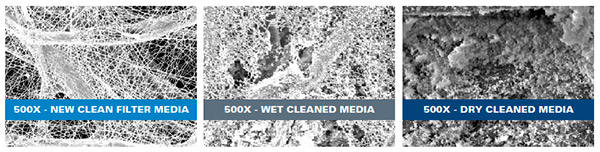

Scanning Electron Microscope (SEM) images show the true difference between new premium efficiency media and the media after it has been wet cleaned or dry cleaned.

*SEM image comparisons of New Clean Filter Media, Wet Cleaned Filter Media and Dry Cleaned Filter Media

The cleaned filter media still has particles clinging to it. Independent laboratory tests* comparing new filter media to cleaned filter media revealed the following:

- Cleaning leads to weakening of the filter media, resulting in reduced tensile strength, shorter life, and potential structural failure

- Cleaning often leads to damaged media pores, resulting in greater depth-loading and reduced filter life

- Cleaning causes a degradation of the nanofibre surface layer, resulting in reduced efficiency at the submicron level - up to 18 per cent reduction at 0.8 microns

- Cleaning offers only a partial recovery in overall filter capacity (dust holding ability) reaching only about 47 per cent; in the filter elements tested, over one half of the filter's life is already used up

- Wet cleaning can remove the flame retardant treatment in filters that were treated to be flame retardant

- More aggressive cleaning processes can create weak spots or even generate holes in the media

Other filter cleaning factors to consider

- Turnaround time for cleaning can be as much as two or three weeks

- A spare set of filters and packaging need to be available for use while filters are out being cleaned

- The shipping and handling of filters being sent out to be cleaned increases the potential for damage to the filters in transit; experience suggests a 10-15 per cent damage rate in this scenario

- Cross contamination of filters can occur while being cleaned

- How do you track your filters to ensure you don't receive another customer's cleaned filter, contaminated with their operation's particulate?

- Contaminants may migrate to the clean side of the filter during cleaning and this can lead to the introduction of the contaminant into the plant environment after reinstallation

- Dry cleaning companies reserve the right to replace damaged or uncleanable filters with new standard grade filters at the customer's expense and they may replace premium efficiency filters with non-premium products

- Mixing cleaned and new filters in a dust collector negatively affects the overall loading and efficiency and will reduce the filter life of the new filters

A comparison of what we can see with the naked eye.

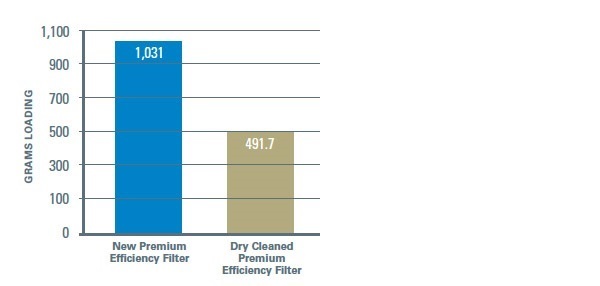

One of the most dramatic differences between a new filter and a dry cleaned filter can be identified in this Loss Of Capacity Chart.

This test data clearly shows dry cleaned filters lose almost 53 per cent of their original dust loading capacity. In other words, cleaned filters provide less than half the filter life performance of new, clean, premium performance filters.

The word to the wise is to think twice before cleaning your dust collector filters. What might appear to be a good deal often is not.

-205x205.jpg)