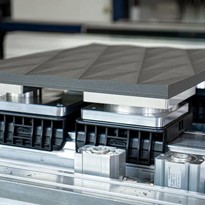

Two important properties to understand when evaluating Stabilising and Jacking products are load bearing capacity and surface area. Products used in stabilising equipment during assembly and maintenance must be both strong (load bearing capacity) to prevent breaking (physical failure), and have sufficient surface area to limit compressing (functional failure) so that the load is distributed over an intended area. Typically, these Stabilising and Jacking products are referred to as “blocks”.

Why are these two properties important to proper block selection?

1. The Stabilising and Jacking block chosen must “support the load of the equipment being supported over a large enough area that the bearing pressure to the ground surface is acceptable [and] provide support to the equipment that is stiff enough that the equipment will not go out of level.

2. Sufficient block surface area is required to spread the load, and Strength/Stiffness is required to prevent the equipment from going out of level.

When evaluating Stabilising and Jacking blocks, it is important to understand the surface area, load bearing capacity, and maximum block working load limit.

Surface area in this context is the portion of the surface area of the block that will be used to support the load.

Load bearing capacity expressed as a weight over an area is the load that can be supported by a unit of the blocks surface area, for example BLOX products have a load bearing capacity of 122kg / cm2 meaning that each square centimetre of the block being used to support the load can bear 122kg.

Maximum block working load limit is the value of the load that can be supported by a block assuming that the whole surface area of that block is being used to support the load.

Definitions

Strength: The ability of the material to support a load without breaking (physical failure)

Stiffness/Rigidity: The ability of the material to resist bending/deflection (functional failure)

A materials strength and stiffness properties are not directly related.

A Block may have enough strength to not break (physically fail). However, this same Block may not be stiff enough to effectively distribute load to the ground due to excessive deflection or (functional failure). If the block is not rigid enough, the load will be concentrated on a smaller area on the block. This is referred to as point loading. Point loading results in increased ground bearing pressure which will cause more block deformation/deflection and could lead to both functional and physical failures. Therefore it is important that the load bearing surface area is sufficient to bear the load. In addition, it is important that when lifting and supporting equipment reference is made to the manufacturers recommended jacking and support points.

Strength and Stiffness Relationships

The strength and stiffness of a Block will depend on the material and the thickness of the material. Material strengths and stiffness properties are generally understood through the use of standardised material testing and analysis.

Plastic is stronger than wood and most wood is stiffer than plastic. Because wood is not as strong as plastic, thickness must be increased to not break (physically fail). Because plastic is not as stiff as wood, thickness will need to be increased to more effectively distribute load and resist deflection (functional failure). Another important consideration with timber cribbing and jacking blocks is no two blocks will ever be the same. Furthermore, as a timber block ages, uncertainty regarding its load-bearing capacity increases. These structural uncertainties, combined with questionable absorbency, risk of splinters, cracking and possible failure under load, it is clear that the time has come for modern, safer alternatives to timber be investigated. Consider for example an application where a piece of wood being used to support a machine is overloaded, its internal fibres damaged. Because the strength of a block relies on the wood fibres being completely connected one to another, in this damaged example load-bearing effectiveness is now compromised. Further, use of such a timber block that shows no visible sign of damage, yet is internally unsound, yields a potentially unsafe work environment. Therefore, properly designed plastic Stabilising and Jacking Blocks can safely support significantly higher loads without risk of breaking (physical failure).

The load bearing capacity and stiffness of a Stabilising and Jacking block is not proportionate to its thickness. Most Stabilising and Jacking blocks are manufactured to strict guidelines to ensure consistency. Typically, a Stabilising and Jacking block will have an identified and test load bearing capacity. As an example, a typical BLOX Industrial Stabilising and Jacking block has a load bearing capacity of 122kg/cm2 at 25°C . Importantly, with temperature variations, load bearing capacity will vary. Consult your Stabilising and Jacking block supplier for technical data. The load bearing capacity is constant and it is important to understand the weight of the equipment being supported and the footprint of the equipment jacking point to ensure optimum spread of the load over the stabilising and jacking block or stacked blocks.

Understanding the difference between strength and support play an essential part when selecting and using stabilising and jacking blocks. Contact Blox Industrial for more information.

-160x160-state_article-rel-cat.jpg)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)