For warehouses, storage, distribution centres, logistics, transport and the like, your processes are the glue that holds everything together.

If you’re looking to expand your warehouse without having to invest in more real estate (rent or buy), a cantilever racking system is a service worth looking into. Maybe you’re someone who would love to import more products and expand a business, but you don’t have floorspace in the current warehouse. You might be satisfied with your current warehouse or distribution centre space but would love to know how to use it more effectively.

Let’s answer the most common cantilever warehouse racking system questions, so you can see if this product is for you.

What is cantilever racking?

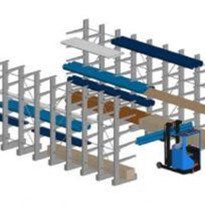

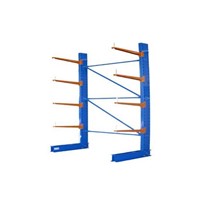

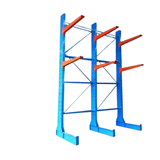

Cantilever industrial racking solutions are an affordable warehouse option for storing items and materials – identifiable and easily accessed when required. This solution is perfect for large, long and odd-sized products that aren’t always simple to store. The racking is a single load bearing upright. Choose the weight abilities, based on your needs.

What are the types of cantilever racking?

Cantilever racking is available in various styles. The type you choose will depend on the type of goods you need to store, as well as your budget. Take ours, for example. There’s a light to heavy-duty configuration, different load options (such as overhead crane) and single or double entry bases.

It’s best to work with a team of storage experts who can create racking shelves and storage solutions to suit your specific needs.

And, what are the benefits of cantilever racking?

With cantilever racking, it’s easier and safer than ever to store, access and distribute your bulky goods. Time is money, especially in this industry – and cantilever racking makes your warehouse solutions run more smoothly.

The cantilever ‘arms’ can be adjusted based on the load, which is convenient to change. For those heavy-duty items (large furniture, automotive parts or long steel pipes), custom cantilever racking is an option.

Enjoy control over your inventory, more streamlined conditions and no more dangerous heavy moving or sorting. With cantilever racking everything is faster and safer. It’s the strongest, most versatile, space-saving racking system there is.

What’s the difference between racking and shelving?

A pallet rack is a single or multi-level storage system, used to support the stacking of items where space is minimal. Items sit on the pallets, otherwise known as skids. Cantilever racking, on the other hand, is designed to safely store large items that are wide, awkward loads such as long, flat, and bulky objects. It’s operated using ‘arms’ and you can customise the set-up based on the stock you have.

How can I identify what warehouse racking is required?

With light, medium and heavy duty racking available, start by looking at all the products you store (and those you plan to in the future). Is it timber, chipboard and tubing? Larger, heavier products like steel, hardwood flooring and other construction materials? Your items will answer this question for you, as well as the expert cantilever racking system team.

Are cantilever racks right for my warehouse?

You might be feeling overwhelmed with this information. We understand. If you feel your business can benefit from cantilever racking, it’s best to talk to our planning experts at Storemax. Our team can help you identify the right solution for your storage and logistics… in line with your goals to deliver awesome service, with less stress, and enjoy higher ROI.

-160x160-state_article-rel-cat.png)