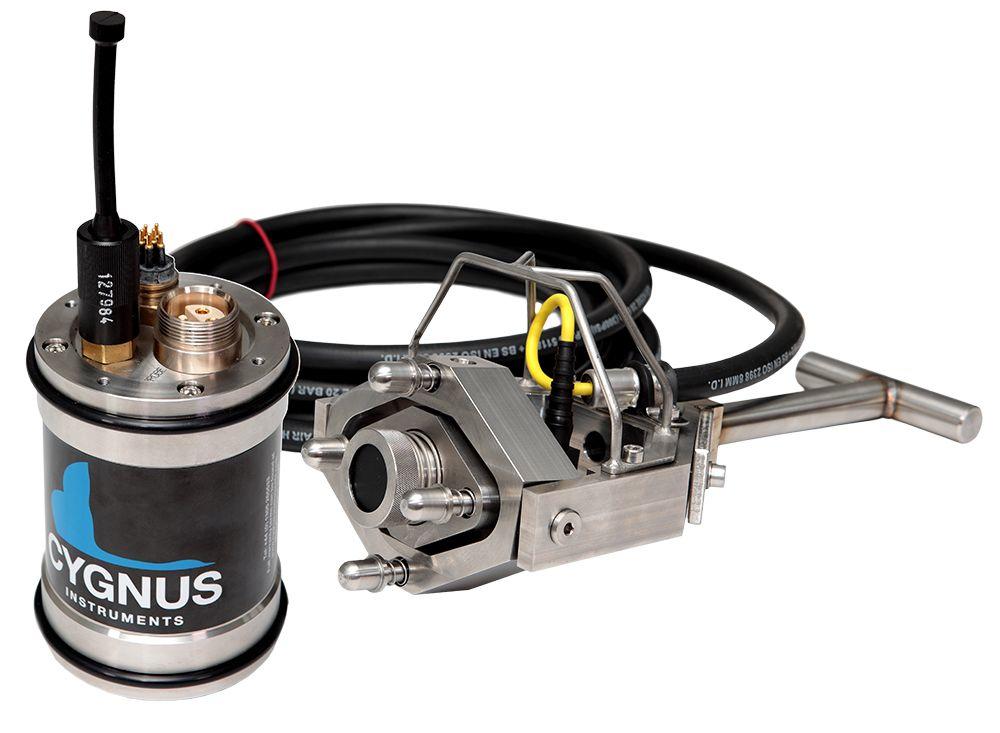

Russell Fraser Sales is proud to announce that Cygnus Instruments, United Kingdom, has developed a new Ultrasonic Flooded Member Detector (FMD) system that will deliver significant cost-savings to the offshore inspection industry. Flooded Member Detection is an inspection regime designed to screen subsea platform structural members for leak defects. A cracked weld can allow the ingress of sea water into the member which may create a point of failure for the structure. There are two recognized non-destructive testing (NDT) techniques that allow for Flooded Member Inspection; the use of a radioactive source Gamma Radiography, or by using Ultrasound.

Inspection using a radioactive source is effective, however the equipment is almost always provided as a service by a third-party contractor and to operate the equipment one, or often two, specialist technicians must travel with the equipment – thus taking up precious bed-space offshore. The Cygnus Ultrasonic Testing (UT) FMD system is simple to operate and thus allows for existing staff from the diving/ROV team to perform the inspection work themselves. This provides a significant cost-saving in personnel. In addition, the operator can perform small packets of FMD inspection work when required as the vessel is not tied to meeting a third-party inspection service provider offshore at a certain time or place. With the Cygnus FMD system, work can be done as and when it is required.

The Cygnus FMD system is the only system that is designed by specialist ultrasonic testing experts. Cygnus has been in the underwater inspection business for nearly 4 decades. To that end, when the Cygnus system presents a Flooded/Not Flooded result, that result is backed up with a true UT A-Scan. This allows for more thorough interpretation of a result. The Cygnus FMD also has a 4-way gimble built around the transducer to ensure correct transducer alignment and a transducer contact sensor to alert the topside technician to the fact that the ROV or diver has made good contact. Furthermore, the Cygnus FMD system’s advanced signal processing and low noise data acquisition will work on thick-walled members and pipes (up to 75mm thick), on heavily corroded members and on buoyancy tanks.

-205x205.jpg)