Many devices are available on the market today for detecting the level of materials in bins, tanks and silos. However, for calculating what’s in inventory sometimes level data just isn’t enough. To estimate the amount of material on hand and the dollar value of that inventory, a single measurement point might not be enough data to calculate an accurate volume estimate. Due to their tendency to form irregular topography in the silo, this can be especially true in powders and solids because many don’t tend to flow freely. If inventory volume is based upon a single measurement from a single point in the silo, the volume estimate has the potential of being very inaccurate.

MULTIPLE POINTS REALLY MATTER

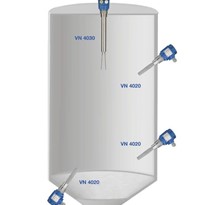

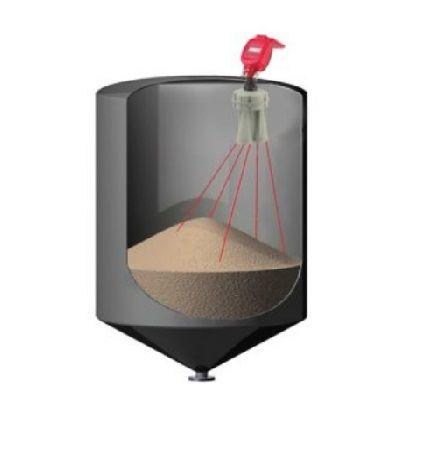

Acoustics-based technology used in sensors referred to as 3DLevelScanners, or generically called scanners, is very different from

other types of sensors. Like the name implies, these devices scan the material surface to take multiple measurements, taking into account the high and low spots in the silo. Scanning the surface also detects conditions such as cone up or cone down as well as buildup that may be

present along the sidewall of the vessel. The data from multiple measuring points is processed using advanced firmware and algorithms,

and when combined with the silo’s parameters loaded into the software, a highly accurate volume estimate can be provided. Additional data,

such as the highest, lowest and average level of the material also is supplied.

GETTING RELIABLE PERFORMANCE IN HEAVY DUST

One of the greatest challenges powders and solids present is the presence of excessive amounts of dust, which can render some types of

sensors inaccurate or unreliable until the dust settles. By operating at very low frequencies, a scanner isn’t bothered by dust and can perform consistently and reliably regardless of the conditions in the vessel. This technology has been proven in many different challenging materials such as alumina powder, carbon black, detergents, polyethylene powder, silica granules, fly ash and talc powder.

SELF-CLEANING SENSORS MINIMIZE MAINTENANCE

A clean sensor will be more reliable and measure accurately, ensuring inventory levels are properly maintained. The unique design and

materials used to manufacture scanners ensure that the surface resists the buildup of dust particles that are suspended in the air at the top of the vessel. Plus, the acoustic pulses make a “chirping” sound that resonates and creates an almost imperceptible vibration that helps keep the inside of the scanner clean. This way, the sensor stays clean and operational without the need for running an air purge to the top of the vessel, which can be costly.

OVERCOMING PROBLEMS WITH CLINGY MATERIALS

When a silo is filled with very dusty materials, it’s important to outfit the silo with a sensor that can stand up in the stickiest situations. For this type of application a scanner that has a Teflon coating on the horn resists dust buildup even when its cold outside and the bin is filled with warm materials. This option is recommended when the sensor is being used to measure clingy materials such as flour, alumina, calcium

carbonate, talc, soda ash, potash, lime, salt, sugar, cocoa, concrete, detergent, or cement.

NON-CONTACT SENSORS PREVENT CONTAMINATION

With an acoustic sensor, there’s nothing that comes into contact with the material, making it very safe to use in powders, granules or other

solids of all types. There’s no risk of equipment being stuck in deep material or becoming detached and potentially damaging structure or

equipment in the bottom of the silo. There’s no need to replace probes or cables that can wear out over time. Eliminating contact with material helps ensure long life with minimal preventive maintenance or cost.

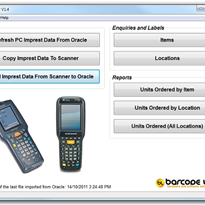

INVENTORY MANAGEMENT WITH FEWER ACCIDENTS

When inventory monitoring is completely automated, there’s no need to climb silos to take measurements. This not only saves time, it eliminates the risk of falls and the resulting injuries and the hassles of insurance and paperwork that comes with accidents. Plants today deal with rigorous OSHA requirements pertaining to climbing and entering silos and risk hefty fines when found in violation. Installing an automated inventory monitoring system allows for material management to be performed from a personal computer in the safety of an office.

?

LEVEL AND VOLUME MEASUREMENT

3DLevelScanners, like most other measurement devices, come in a variety of models and offer a wide range of options to tailor the device

to the application. To select the right model for an application, it’s extremely important to communicate your expectations of the

technology and how you plan to use the data that you get from the device. Many plants are focused upon having a very high level of

inventory accuracy. Accuracy of the scanner is driven by a number of variables, starting with information about the size of the vessel, the

presence of structure inside it, and the material that’s being measured.

The installation location also is important as scanner technology measures multiple points, so the device needs to have a clear view of

the material surface. The most basic model of a scanner is referred to as an RL, which is short for reliable level. This model measures material in a narrow beam directly below the device, penetrating high levels of dust, and performing where other types of level sensors become unreliable or inaccurate. This model is most often used when highly reliable level measurement data is needed on a continual basis. This model is frequently applied in materials that are less prone to excessive buildup and in narrow or smaller silos.

When more than simple level data is needed, the S model is designed to determine volume based upon an average level in the bin from multiple measurements taken within a 30° beam angle. This model often is used in narrow silos with diameters up to 16 ft and heights up to 200 ft. This model can also be used in wider silos, but with diminished accuracy as the 30° beam angle may not cover the entire material surface.

The M model takes measurements from a broader 70° beam angle making it appropriate for larger diameter silos and silos with uneven

material topography. It also generates additional data including the lowest, highest, and average distances based upon multiple

measurements.

Due to its ability to scan the material surface and take into account irregularities, a scanner can provide a very high level of volume accuracy from between one and three percent. At the top of the model spectrum is the model MV, which does everything the M does, plus adds a unique visualization feature. Using complex algorithms and a lot of processing power, this model generates a 3D image that indicates where the high and low spots are in the silo, shows if the cone is up or down, and detects sidewall buildup. This additional feature can be used to help manage filling and emptying points as well as detect if maintenance is needed to clean out buildup. This model is often used in large silos and in flour-like powders and other types of materials that tend to pile up unevenly.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)