Background

Zirconium oxygen probes are the most common method of controlling combustion and heat treatment processes. Novatech Controls have thousands of systems installed in power stations, petrochemical plants, heat treatment hardening furnaces and annealing furnaces, and a variety of incinerators, cement plants and drying ovens. All of these processes have different requirements, and pose different conditions to the components of the probe exposed to the process.

Failure modes

The useful life of the probe is limited by the first component of the probe to fail. The failure may be a slow deterioration or a sudden change of the working condition of one of the vital components.

Components that may have a sudden failure are:

- The heater in heated probes (open circuit or short circuit to ground)

- The thermocouple (cracking thermal junction causing an open circuit)

- Outer metal sheathing (breakage through corrosion or abrasion, or chemical attack)

- The ceramic components of the probe (physical or thermal shock)

Components that will slowly deteriorate are:

- The electrode coating of the zirconia sensor

- The thermocouple (oxidation, grain growth)

- The internal electrode conductor (oxidation, grain growth)

Oxygen Sensor Impedance

There is not a definite impedance at which a sensor can be said to have failed. As the electrode deteriorates, the impedance will rise. However the sensor oxygen reading is not affected by the loss of electrode material over a wide range if impedances (up to tens of k?). In fact, if the temperature of the sensor is over 850°C the sensor will read the correct oxygen concentration without any electrode material as long as there is no other deterioration of the electrode connections. The response time will usually increase as the electrode ages.

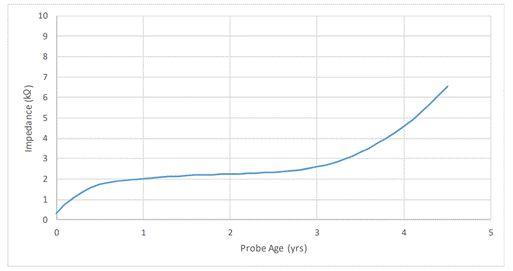

The above graph shows how sensor impedance will typically vary with use. The sensor impedance is the sum of the electrode impedance and the electrolyte impedance. The electrode impedance is the part that will increase as the probe ages. Complicating the interpretation of the sensor impedance measurement is that the electrolyte impedance will be markedly lower at higher sensor temperatures. This is taken into account in the determination of the alarm status of the Novatech analysers. As an indication of probe life, the Novatech analyser will raise a “Sensor Fail” alarm when the sensor is over 9k? when the sensor temperature is 720°C.

Summary

An oxygen probe will fail through a number of failure modes, only one of which has a measurable quantity related to the potential failure. Although most probes are taken out of service because the sensor electrode has deteriorated, the impedance changes must be taken as a series of readings over a period of several weeks. The best indication of an impending probe failure is in a series of impedance readings showing a definite and rapid increase.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-205x205.jpg)

-205x205.jpg)