But the changes haven’t stopped there. The rising lithium-powered forklifts have become the game-changer in the industry. However, most people stop switching to lithium-ion (Li-ion) due to its higher initial costs compared to lead-acid alternatives. This article is going to explain why Li-ion forklifts worth the extra price.

Basic Difference

Lead-acid battery, first invented and used back in 1859, contains a case and cells with electrolyte mixture, water, and sulfuric acid. Lead-acid battery involves chemical reactions with lead plates and sulfuric acid to create lead sulphate build-up. It requires the periodic adding of water and maintenance.

Li-ion battery, a new word in the forklifts industry, has been introduced in consumer markets on phones and other small devices since the 1980s. After decades of improvement, Li-ion battery is now used in large equipment such as cars and forklifts due to its superior performance and reduced costs over their lifetime.

Some people might still hesitate about if they should invest in Li-ion forklifts. There are few reasons that you should know:

Benefits of Li-ion Batteries

Operational Efficiency

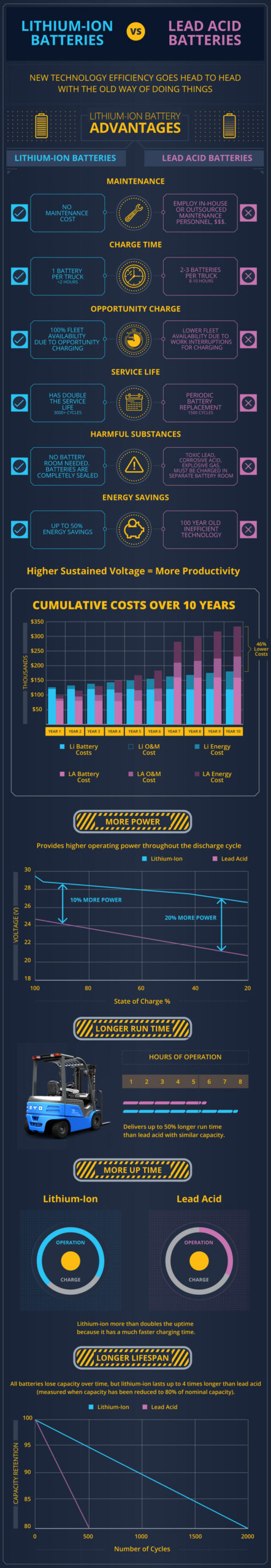

Comparing to lead-acid batteries, which can only be discharged to 50% – 30%, Li-ion batteries can safely handle up to 90%. It means longer operational activity and less costly downtime where workers have to swap or charge batteries.

Cycle Life

Li-ion batteries require zero maintenance and still have 80% of their original capacity after 3000 cycles. In comparison, lead-acid batteries have an average of 1500 cycles if maintained well. Without maintenance, this drops to 6-700 at best. In financial terms, lead-acid forklifts averagely require a battery replacement every 2-3 years (or equivalent 5,000 hours). However, your Li-ion forklifts would still be under warranty in 5 years (or equivalent 10,000 hours).

Charging cost and time reduction

Lead-acid batteries have a warm-up period before charging, requiring more energy and a longer time to be fully charged. Moreover, its required “cool-down” period extends its charging time to over 8 hours. In addition, due to its design, every plug-in & out indicates one charging cycle, which means you cannot stop in the middle of the charging time. This restrained lead-acid forklift from long time operation unless you are willing to pay an extra $5,000 for a spare battery.

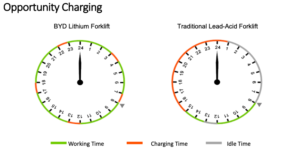

In contrast, Li-ion batteries allow faster and more efficient charging. It would increase energy efficiency by 30-40% and requires less than 30% charging time comparing to lead-acid batteries. All energy would go directly into the battery. On average, it would only take two hours to get fully charged. Moreover, our BYD Li-ion forklifts provide a quick charger as an option that allows the forklifts to be fully charged within one hour.

Most importantly, Li-ion batteries enable opportunity charging during any spare time, just like your phone. Based on our customer feedback, a one-hour charging during lunchtime would be enough for another entire 4-hour shift. Hence, you would never need a spare unit for replacement. One Li-ion forklift would allow you to work 24/7.

Averagely, warehouse facilities spends 15% of its operating budget on energy costs. Whenever you can make that number go down, profits go up.

Other Benefits

- Clean energy with no hazardous acid liquid and no harmful emission;

- Increased working space as no spare unit or charging centre required;

- Li-ion forklift batteries maintain their capacity in cold temps much better than lead-acid and can be fast-charged in cold temps, even inside freezers.

- All Li-ion batteries are equipped with a BMS to ensure safety for the battery. While their primary function is safety, these systems can be programmed with advanced algorithms to benefit the user with higher measurement precision, performance, and case-specific solutions that enhance the battery and the quality of the application;

Final Words

Overall, based on our estimation, a 2.5 ton BYD Li-ion forklift would help you save up to $30 per day by cutting down labour hours for maintenance, energy costs and even having a replacement unit.

Of course, forklift battery technology is always changing and undoubtedly there will be a new type of battery in the future. In fact, there already is a new type called ‘super capacitor batteries’ (watch the YouTube if you are enthusiastic about science!) that have an even higher density and operational cycle than Li-ion.

However, Li-ion battery would definitely become the new generation of forklifts power. Don’t wait until you wasting all the money!

Still wondering if Li-ion battery would perfectly fit your business? eForklift can help. From identifying the right battery to sourcing new equipment, we have got you covered. Our team of dedicated professional material handling experts are ready to help you find the right solution.

References:

Corrosion Doctors. (n.d.). Biographies: Gaston Planté (1834-1889). http://www.corrosion-doctors.org/Biographies/PlantelBio.htm.

Flux Power. (n.d.). How To Choose The Right Forklift Battery. https://www.fluxpower.com/how-to-choose-the-right-forklift-battery

OUC. (n.d.). Warehouse. https://ouc.bizenergyadvisor.com/article/warehouses.

Undecided with Matt Ferrell. (2020, Sep 1). Supercapacitors explained – the future of energy storage? [Video]. Youtube. https://youtu.be/-7T-6XdiRTw.

-205x205.jpg)