Thermocouples are an electrical device consisting of two dissimilar electrical conductors forming an electrical junction. A thermocouple produces a temperature-dependent voltage which is interpreted to measure temperature. Commercial thermocouples are inexpensive, interchangeable, are supplied with standard connectors, and can measure a wide range of temperatures. In contrast to most other methods of temperature measurement, thermocouples are self-powered and require no external form of excitation.

The thermocouples’ ability to measure temperature across a wide range, from -200 Degrees Celsius (-328 Degrees Fahrenheit) to extreme high temperatures up to +2300 Degrees Celsius (+4172 degrees Fahrenheit) makes them very versatile. Enabling thermocouples to be suitable to various Industries and application such steel manufacturing, glass production, aerospace engineering, medical and scientific research.

What are some of the advantages of a thermocouple?

Thermocouples have a fast response time, allowing for real-time temperature monitoring and control in industrial processes They quickly detect changes in temperature making them ideal for applications that require immediate adjustment based on temperature fluctuation.

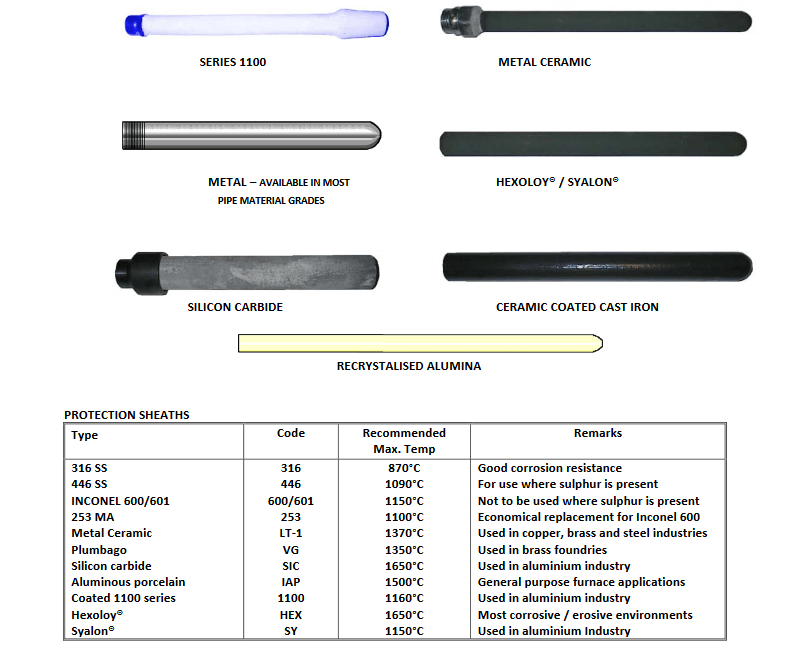

Industrial environments vary and some are harsher, with exposure to extreme temperatures, vibrations, moisture, and corrosive chemicals. Thermocouples are designed and built to withstand these conditions, manufactured with numerous materials such as ceramics or metal protection tubes to ensure durability and resistance to mechanical stress, corrosion, and environmental factors while still providing reliable temperature measurements.

With advancements in technology and calibration techniques modern thermocouples can achieve high and precision temperature accuracies within a few degrees Celsius (Fahrenheit). Which meets the stringent requirements for industries such as food processing, pharmaceutical, and scientific research.

Thermocouples offer an excellent balance between performance and cost, making them a preferred choice for temperature measurement in many industrial processes. The cost of a thermocouple is generally lower than that of alternative sensors, such as resistance temperature detectors (RTD’s) or infrared pyrometers. The thermocouples durability and longevity contribute to long term cost savings.

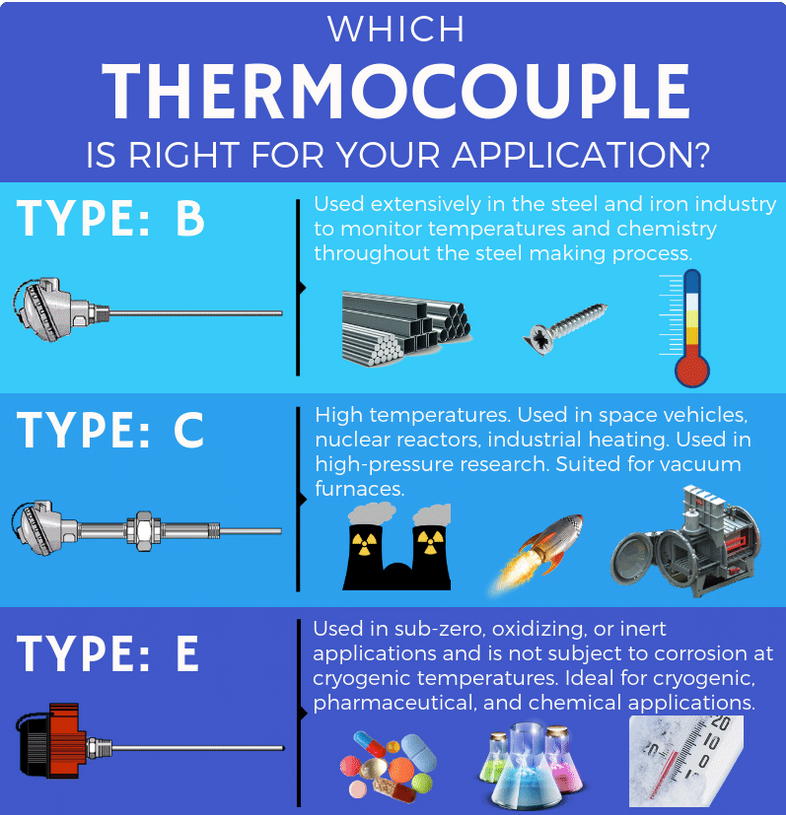

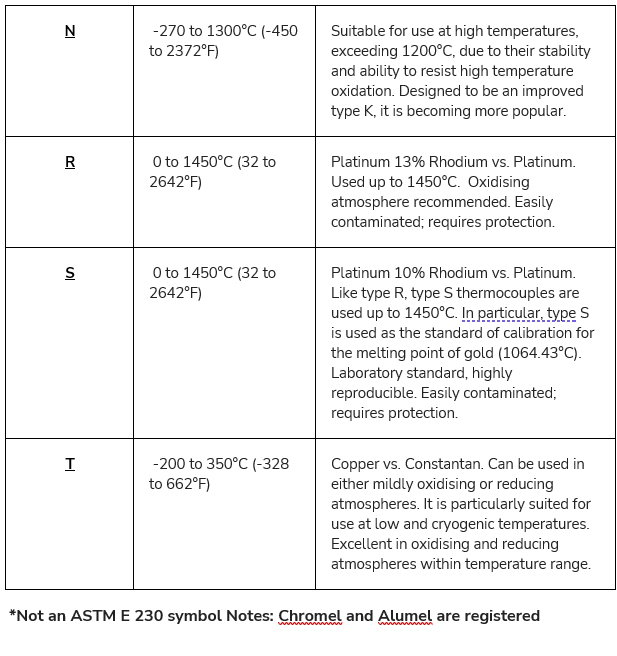

Thermocouples offer a wide range of configurations and types to suit various industrial applications. Different combinations of metals result in distinct thermocouple types, such as Type K, Type J and Type T and man more types. Each type of thermocouple has its own temperature range, sensitivity, and resistance to different environmental factors. This allows a thermocouple to be manufactured and tailored to your temperature measurement solution and industrial requirements.

With electrical standardised colour codes and characteristics this enables a thermocouple to be compatible and interchangeable with a wide range of instruments and control systems. A thermocouple can easily be integrated into an existing industrial setup without modification or additional equipment.

What are some of the types of Thermocouples?

- Type K: the most common type of thermocouple, it is inexpensive, reliable, and accurate.

- Type J: also, very common, but has a smaller temperature range and has a shorter lifespan at higher temperatures than the type K.

- Type T: a stable thermocouple and is used for lower temperatures.

- Type E: has a stronger signal and a higher accuracy.

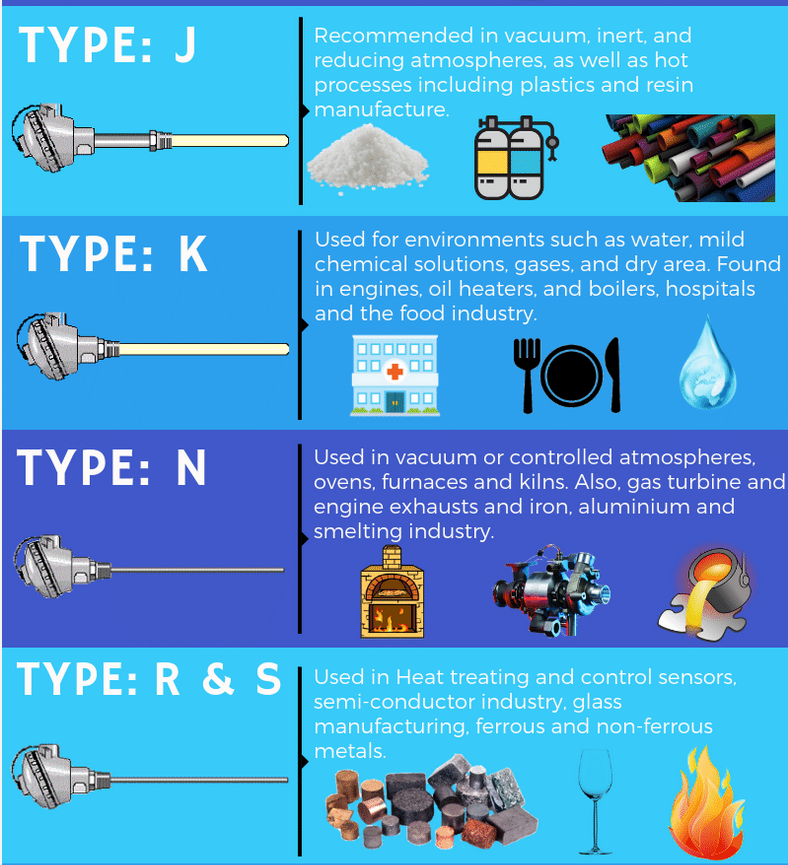

- Type N: shares the same accuracy and limits as K but it slightly more expensive.

- Type S: for very high temperatures and is used mainly in the pharmaceutical industry.

- Type R: like type S in terms of performance and is often used in lower temperature because of its accuracy and stability.

- Type B: has the highest temperature range out of all the thermocouples.

What are some Industrial Thermocouples designs.

Industrial Thermocouples

General Purpose Thermocouples

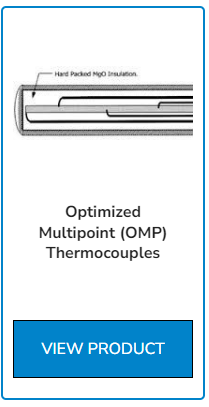

Multipoint Thermocouples

In conclusion thermocouples play a vital role in industrial temperature measurement, offering a wide temperature range, fast response times, durability, accuracy, and versatility. Their applications span across diverse industries, ensuring process control, product quality, and safety. Proper installation, calibration, and maintenance are essential for reliable and accurate temperature measurements. The ongoing development of thermocouple technology promises further improvements in accuracy, sensitivity, and robustness, further solidifying their importance in industrial temperature measurement.

Pyrosales has extensive knowledge and experience in temperature management and process control. We provide advice, design, repair, and fabrication to our clients on a wide range of industries, uses, and capabilities of temperature management.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-205x205.jpg)